- Branches

- Systems

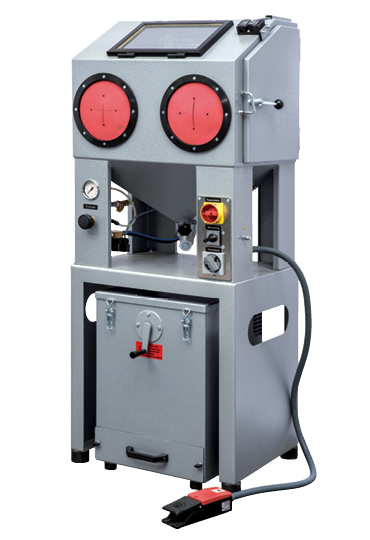

- Injector blasting systems

- Rotary table systems

- Rotary basket systems

- Fine blasting systems

- Vapour blasting systems

- Wet blasting systems

- Tumblast systems

- Dust separators

- Customized models

- Individual blasting system

- Satellite blasting systems

- Rotary indexing table blasting systems

- Blasting systems - deburr blasting

- Blasting systems - lap blasting

- Production blasting systems

- Refinement blasting systems

- Pressure blasting cabins

- Instruction

- Technology

- Surface technology in blasting

- Mechanical deburring with blasting technology

- Surface refining by blasting

- Injector blasting principle

- Wet blasting principle

- Vapour blasting principle

- Grit for Efficient Blasting Technology

- Decoating technology and blasting technology

- Decoating technology and blasting technology

- Decoating technology and blasting technology

- Decoating technology and blasting technology

- Decoating technology and blasting technology

- Abrasives

- Applications

- Performance

- Company