Injector blasting systems for the use

of fine-grained, inert and mineral blasting materials

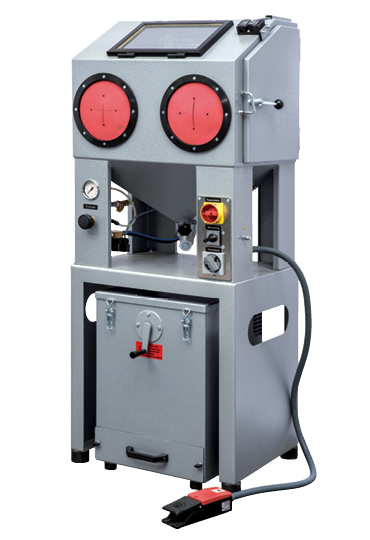

SIGG Strahltechnik offers standard injector blasting systems in various sizes (600 mm – 2000 mm) within its portfolio. By their use metal parts can be cleaned, de-rusted, de-burred, roughened and lapped. Injector blasting systems are optimally suitable for the use of fine-grained, inert and mineral blasting abrasives, which can easily be exchanged. The universally applicable machines with their clearly visible blasting chambers are extremely robust and ergonomically built.

Folding front door at the blasting cabinet

The manual operation of the closed, illuminated and well ventilated injector blasting system runs smoothly and features an easy handling. This is ensured, among other things, by the folding front door of the blasting cabinet. In order to keep the blasting of small parts particularly economical, it is possible to equip these systems with a rotary basket. For large parts SIGG Strahltechnik offers the option of a manually operated rotary table as either a normal or a mobile version.

Injector blasting instead of pressure blowers

Wherever high blasting energy or the large scattering of blasting wheels and pressure blowers is unwanted or unnecessary, injector blasting systems are applied. This prevents primarily small or delicate work pieces from being damaged. The process has also the advantage that small quantities of blasting material can be skidded with low, adjustable speed onto a relatively small surface.

Short acceleration distance

The resulting expansion of the compressed air generates a vacuum used for the suction of the blasting abrasive. The mixing of blasting material and carrying air takes place in the dispenser located at the bottom of the collecting hopper. The blasting abrasive gets sucked up by the injector air generated by the gun before being further accelerated by the supplied compressed air inside the body of the gun. The short acceleration distance of 80 to 100 mm results in a blasting abrasive‘s muzzle velocity of ca. 10 m/sec.

A constant jet is of vital importance, particularly for automatic systems, because of the omitted pressure blower’s interruptions during the refill of the vessel. Thus, the injector blasting process is recommended in all situations where a different dry blasting process is effectively too rough, too costly or of unnecessary capacity.

Injector blasting cabinets in various versions

For semi-automatic operations with manual loading and unloading of parts, it is possible to equip the blasting cabinets with satellite tables, conveyor belts, transport rollers, roller tracks, trolleys, turntables and rotary baskets. Except the batch wise operating rotary drums and rotary baskets, systems of this kind can as well be fully automated by implementing adequate feeding magazines and unloading devices. The blasting process always takes place within closed cabinets, while charging- and unloading devices operate externally. Would you like to learn more about injector blasting systems, a blasting process that suits your needs, or the values of our blasting cabinets? Then please do not hesitate to call or contact us.

![[Translate to Englisch:] Injektoranlagen TR 70 [Translate to Englisch:] Injektoranlagen TR 70](/fileadmin/user_upload/produktbilder/Neue_Produktabbildungen/TR70.jpg)